Development Trends in the Resistor Industry

I. Introduction

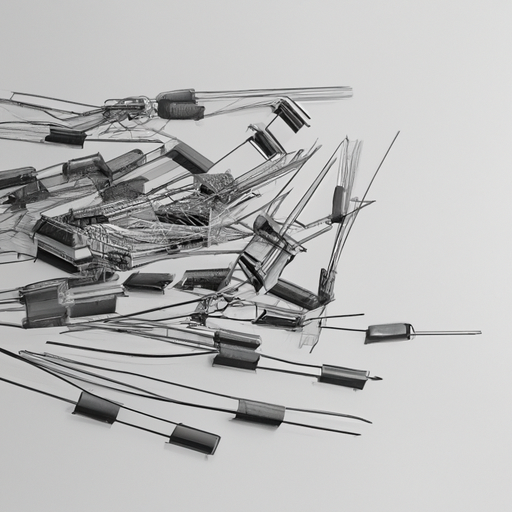

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. They are essential in a wide range of applications, from simple household devices to complex industrial machinery. The resistor industry plays a vital role in the broader electronics market, influencing the performance, efficiency, and reliability of electronic systems. This article aims to explore the current and emerging trends in the resistor industry, shedding light on how these trends are shaping the future of electronics.

II. Historical Context

A. Brief Overview of the Evolution of Resistors

The history of resistors dates back to the early days of electrical engineering. Initially, resistors were made from simple materials like carbon and wire. As technology advanced, so did the materials and manufacturing processes used to create resistors. The introduction of film technology in the mid-20th century marked a significant turning point, allowing for more precise and reliable resistors.

B. The Growth of the Electronics Industry and Its Impact on Resistor Development

The rapid growth of the electronics industry has had a profound impact on resistor development. As consumer electronics became more prevalent, the demand for smaller, more efficient components surged. This demand has driven innovation in resistor design and manufacturing, leading to the development of new materials and technologies that enhance performance and reliability.

III. Current Trends in the Resistor Industry

A. Miniaturization of Resistors

One of the most significant trends in the resistor industry is the miniaturization of components. As consumer electronics continue to shrink in size, there is an increasing demand for smaller resistors that can fit into compact designs. Advances in manufacturing techniques, such as surface mount technology (SMT), have enabled the production of miniature resistors without compromising performance.

B. Increased Power Ratings

With the rise of high-performance applications, there is a growing need for resistors that can handle higher power loads. This trend is particularly evident in the automotive and industrial sectors, where resistors must withstand extreme conditions. Manufacturers are responding by developing resistors with enhanced power ratings, ensuring they can meet the demands of modern applications.

C. Enhanced Precision and Tolerance

In today's electronic applications, accuracy is paramount. The demand for precision resistors has increased as industries such as telecommunications, aerospace, and medical devices require components with tight tolerances. Manufacturers are investing in advanced production techniques to create precision resistors that meet these stringent requirements.

D. Use of Advanced Materials

The shift towards high-performance materials is another key trend in the resistor industry. Traditional materials are being replaced with advanced options such as thin-film and thick-film technologies, which offer improved performance characteristics. Additionally, the impact of nanotechnology is becoming more pronounced, enabling the development of resistors with superior performance metrics.

E. Environmental Considerations

As environmental concerns grow, the resistor industry is also adapting. There is a push for eco-friendly materials and manufacturing processes, driven by both consumer demand and regulatory requirements. Manufacturers are increasingly focusing on sustainability, ensuring that their products comply with global environmental regulations while minimizing their ecological footprint.

IV. Emerging Trends in the Resistor Industry

A. Smart Resistors and IoT Integration

The integration of smart technology into resistors is an emerging trend that is gaining traction. Smart resistors equipped with integrated sensors can provide real-time data on performance and environmental conditions. This capability is particularly relevant in the context of the Internet of Things (IoT), where connected devices require components that can communicate and adapt to changing conditions.

B. Customization and Application-Specific Resistors

As industries become more specialized, there is a growing demand for customized resistors tailored to specific applications. Manufacturers are increasingly collaborating with end-users to develop application-specific solutions that meet unique performance requirements. This trend is fostering innovation and driving the development of new resistor designs.

C. Automation and Industry 4.0

The advent of Industry 4.0 is transforming the manufacturing landscape, and the resistor industry is no exception. Automation is streamlining production processes, improving efficiency, and reducing costs. Additionally, the use of artificial intelligence (AI) and machine learning in design and production is enabling manufacturers to optimize resistor performance and enhance quality control.

D. Global Supply Chain Dynamics

Geopolitical factors are influencing the global supply chain for resistors. Manufacturers are facing challenges related to sourcing materials and navigating international trade regulations. In response, companies are developing strategies to enhance resilience and sustainability in their supply chains, ensuring they can adapt to changing market conditions.

V. Challenges Facing the Resistor Industry

A. Competition and Market Saturation

The resistor market is becoming increasingly competitive, with numerous players vying for market share. This saturation presents challenges for manufacturers, who must find ways to differentiate their products and innovate to stay ahead. Strategies such as focusing on niche markets or developing unique technologies can help companies maintain a competitive edge.

B. Technological Limitations

While advancements in technology have propelled the resistor industry forward, there are still challenges to overcome. Scaling production of advanced resistors can be difficult, and manufacturers must balance performance with cost-effectiveness. Finding the right materials and processes to achieve this balance is crucial for long-term success.

C. Regulatory and Compliance Issues

Navigating international standards and regulations can be a complex task for resistor manufacturers. Compliance with these regulations is essential, as failure to do so can result in significant penalties and damage to a company's reputation. Manufacturers must stay informed about changing regulations and adapt their processes accordingly.

VI. Future Outlook

A. Predictions for the Resistor Market Over the Next Decade

Looking ahead, the resistor market is expected to continue evolving in response to technological advancements and changing consumer demands. The trend towards miniaturization and increased power ratings is likely to persist, with manufacturers focusing on developing innovative solutions that meet these needs.

B. Potential Technological Breakthroughs and Their Implications

Technological breakthroughs in materials science and manufacturing processes could significantly impact the resistor industry. Innovations such as advanced nanomaterials and 3D printing may enable the creation of resistors with unprecedented performance characteristics, opening new possibilities for electronic design.

C. The Role of Resistors in the Future of Electronics and Technology

As electronics continue to advance, resistors will remain a critical component in ensuring the functionality and reliability of devices. Their role in emerging technologies, such as IoT and smart devices, will only grow, making it essential for manufacturers to stay ahead of trends and adapt to the changing landscape.

VII. Conclusion

In summary, the resistor industry is undergoing significant transformation driven by current and emerging trends. From miniaturization and increased power ratings to the integration of smart technology and environmental considerations, manufacturers are adapting to meet the demands of a rapidly changing market. While challenges such as competition and regulatory compliance persist, the future of the resistor industry looks promising, with innovation and adaptation at the forefront of its evolution.

VIII. References

A comprehensive list of academic papers, industry reports, and articles used for research, along with additional resources for further reading on resistor technology and trends, would be included here to provide readers with a deeper understanding of the topic.

Development Trends in the Resistor Industry

I. Introduction

Resistors are fundamental components in electronic circuits, serving the critical function of controlling current flow and voltage levels. They are essential in a wide range of applications, from simple household devices to complex industrial machinery. The resistor industry plays a vital role in the broader electronics market, influencing the performance, efficiency, and reliability of electronic systems. This article aims to explore the current and emerging trends in the resistor industry, shedding light on how these trends are shaping the future of electronics.

II. Historical Context

A. Brief Overview of the Evolution of Resistors

The history of resistors dates back to the early days of electrical engineering. Initially, resistors were made from simple materials like carbon and wire. As technology advanced, so did the materials and manufacturing processes used to create resistors. The introduction of film technology in the mid-20th century marked a significant turning point, allowing for more precise and reliable resistors.

B. The Growth of the Electronics Industry and Its Impact on Resistor Development

The rapid growth of the electronics industry has had a profound impact on resistor development. As consumer electronics became more prevalent, the demand for smaller, more efficient components surged. This demand has driven innovation in resistor design and manufacturing, leading to the development of new materials and technologies that enhance performance and reliability.

III. Current Trends in the Resistor Industry

A. Miniaturization of Resistors

One of the most significant trends in the resistor industry is the miniaturization of components. As consumer electronics continue to shrink in size, there is an increasing demand for smaller resistors that can fit into compact designs. Advances in manufacturing techniques, such as surface mount technology (SMT), have enabled the production of miniature resistors without compromising performance.

B. Increased Power Ratings

With the rise of high-performance applications, there is a growing need for resistors that can handle higher power loads. This trend is particularly evident in the automotive and industrial sectors, where resistors must withstand extreme conditions. Manufacturers are responding by developing resistors with enhanced power ratings, ensuring they can meet the demands of modern applications.

C. Enhanced Precision and Tolerance

In today's electronic applications, accuracy is paramount. The demand for precision resistors has increased as industries such as telecommunications, aerospace, and medical devices require components with tight tolerances. Manufacturers are investing in advanced production techniques to create precision resistors that meet these stringent requirements.

D. Use of Advanced Materials

The shift towards high-performance materials is another key trend in the resistor industry. Traditional materials are being replaced with advanced options such as thin-film and thick-film technologies, which offer improved performance characteristics. Additionally, the impact of nanotechnology is becoming more pronounced, enabling the development of resistors with superior performance metrics.

E. Environmental Considerations

As environmental concerns grow, the resistor industry is also adapting. There is a push for eco-friendly materials and manufacturing processes, driven by both consumer demand and regulatory requirements. Manufacturers are increasingly focusing on sustainability, ensuring that their products comply with global environmental regulations while minimizing their ecological footprint.

IV. Emerging Trends in the Resistor Industry

A. Smart Resistors and IoT Integration

The integration of smart technology into resistors is an emerging trend that is gaining traction. Smart resistors equipped with integrated sensors can provide real-time data on performance and environmental conditions. This capability is particularly relevant in the context of the Internet of Things (IoT), where connected devices require components that can communicate and adapt to changing conditions.

B. Customization and Application-Specific Resistors

As industries become more specialized, there is a growing demand for customized resistors tailored to specific applications. Manufacturers are increasingly collaborating with end-users to develop application-specific solutions that meet unique performance requirements. This trend is fostering innovation and driving the development of new resistor designs.

C. Automation and Industry 4.0

The advent of Industry 4.0 is transforming the manufacturing landscape, and the resistor industry is no exception. Automation is streamlining production processes, improving efficiency, and reducing costs. Additionally, the use of artificial intelligence (AI) and machine learning in design and production is enabling manufacturers to optimize resistor performance and enhance quality control.

D. Global Supply Chain Dynamics

Geopolitical factors are influencing the global supply chain for resistors. Manufacturers are facing challenges related to sourcing materials and navigating international trade regulations. In response, companies are developing strategies to enhance resilience and sustainability in their supply chains, ensuring they can adapt to changing market conditions.

V. Challenges Facing the Resistor Industry

A. Competition and Market Saturation

The resistor market is becoming increasingly competitive, with numerous players vying for market share. This saturation presents challenges for manufacturers, who must find ways to differentiate their products and innovate to stay ahead. Strategies such as focusing on niche markets or developing unique technologies can help companies maintain a competitive edge.

B. Technological Limitations

While advancements in technology have propelled the resistor industry forward, there are still challenges to overcome. Scaling production of advanced resistors can be difficult, and manufacturers must balance performance with cost-effectiveness. Finding the right materials and processes to achieve this balance is crucial for long-term success.

C. Regulatory and Compliance Issues

Navigating international standards and regulations can be a complex task for resistor manufacturers. Compliance with these regulations is essential, as failure to do so can result in significant penalties and damage to a company's reputation. Manufacturers must stay informed about changing regulations and adapt their processes accordingly.

VI. Future Outlook

A. Predictions for the Resistor Market Over the Next Decade

Looking ahead, the resistor market is expected to continue evolving in response to technological advancements and changing consumer demands. The trend towards miniaturization and increased power ratings is likely to persist, with manufacturers focusing on developing innovative solutions that meet these needs.

B. Potential Technological Breakthroughs and Their Implications

Technological breakthroughs in materials science and manufacturing processes could significantly impact the resistor industry. Innovations such as advanced nanomaterials and 3D printing may enable the creation of resistors with unprecedented performance characteristics, opening new possibilities for electronic design.

C. The Role of Resistors in the Future of Electronics and Technology

As electronics continue to advance, resistors will remain a critical component in ensuring the functionality and reliability of devices. Their role in emerging technologies, such as IoT and smart devices, will only grow, making it essential for manufacturers to stay ahead of trends and adapt to the changing landscape.

VII. Conclusion

In summary, the resistor industry is undergoing significant transformation driven by current and emerging trends. From miniaturization and increased power ratings to the integration of smart technology and environmental considerations, manufacturers are adapting to meet the demands of a rapidly changing market. While challenges such as competition and regulatory compliance persist, the future of the resistor industry looks promising, with innovation and adaptation at the forefront of its evolution.

VIII. References

A comprehensive list of academic papers, industry reports, and articles used for research, along with additional resources for further reading on resistor technology and trends, would be included here to provide readers with a deeper understanding of the topic.